Setting up the “L” Shaped Garage to facilitate wheel alignment caused me to purchase the Atlas wheel stands, Intercomp race scales, and ART laser Toe Angle Gauge. To align the Lotus Exige in particular I purchased the Flyin’ Miata hub stands. While the journey so has been interesting and fun the time has come to get to work and actually align a car.

In the interests of full disclosure… I’m writing this blog entry shortly after completing the wheel alignment on the Lotus. The process I’m going to describe here includes a number of additional steps included in this first effort. Specifically I chose to work from from both the Flyin’ Miata hub stands and also traditional “slip plates” in an effort to compare and contrast both the effort involved and the results.

As a first order of business I added weight to the drivers seat and disconnected the front sway bar. I used 40 lb. bags of water softener salt to ballast the drivers seat with 200 pounds of weight. The salt bags allow you to distribute the weight across the seating position nicely.

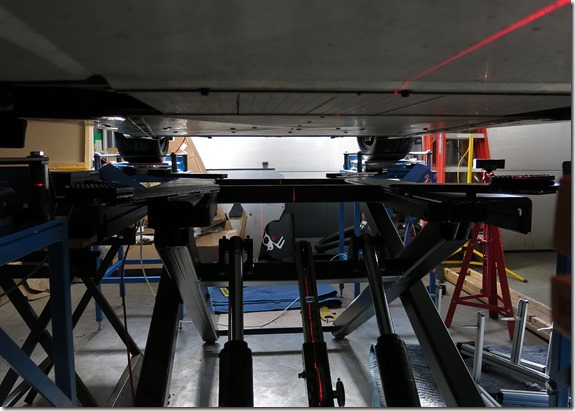

The Lotus Exige has a new set of adjustable suspension dampers (shock absorbers) and requires not only a wheel alignment but also ride height adjustment and corner weighting. The first step is to get the wheel stands leveled and the tops of the race scales all in the same plane. The first image below shows the left front stand with a race scale, and slip plates under the front wheel of the Lotus. Here you can see the line from the laser level striking the exposed perimeter of the top slip plate at both the front and rear wheels. The laser is a very convenient way to get the stands set up and close to level.

To ensure the wheel stands are level I have a small two-axis bubble level on top of each scale and also employed a long (78”) carpenters level between the stands.

With the stands leveled and a line level in place under the car we can now measure ride height with a small square. Lotus identifies four positions on the chassis where ride is measured. Holding the square up against these spots allows us to directly measure ride height at each position.

As seen here… There is plenty of clearance under the car to make these measurements.

Setting the ride height and corner weights is an iterative process. I first made sure the spring perches on the front and rear dampers were set to approximately the same position on the shocks. Then set the car down on the wheel stands and took a first set of ride height measurements.

Next I lifted the car… removed the wheels… and made changes to the position of the spring perches to drive the ride heights up or down paying little (if any) attention to the corner weights. In the case of the Lotus I was able to get the ride heights where I wanted them on the second time through the process.

On the third pass through this process I made spring perch adjustments meant to drive the cross corner weights toward 50%. That is… I focused my attention on the scale readings largely ignoring the ride heights. This third iteration resulted in an 8 lb. difference (49.8%). Plenty good for now.

With the ride height and corner weights close I moved on to taking a set of alignment measurements using the ART Laser Toe Angle Gauge. The front wheels measured Toe OUT: 41 minutes… The rear Toe IN: 12 minutes. This works out to something like .20” (5mm) Toe OUT front and .06” (1.5mm) Toe IN rear.

The ART system sits nicely on top of the guards built for the wheel stands and is a very nice way to quickly measure Toe Angle on a vehicle. It is important to note that it does not tell you anything about thrust angle and requires the wheel remain in place on the car. Although adjusting the tie rod ends is probably possible with the wheel installed on the car it would certainly be difficult on a vehicle with as little space underneath as the Lotus.

No comments:

Post a Comment