Reading through the pages of lotus Talk inevitably brings you to not only many different implementations of the string method for wheel alignment but also to Carl Schulhof's ingenious system for measuring thrust angle using strings. Like many others I was initially confused because he implements strings to measure thrust angle. His method is so ingenious in fact; it took me an embarrassingly long time to figure out that thrust angle is what he's actually measuring.

Watch Carl explain his methods in a seminar at Sector 111 here…

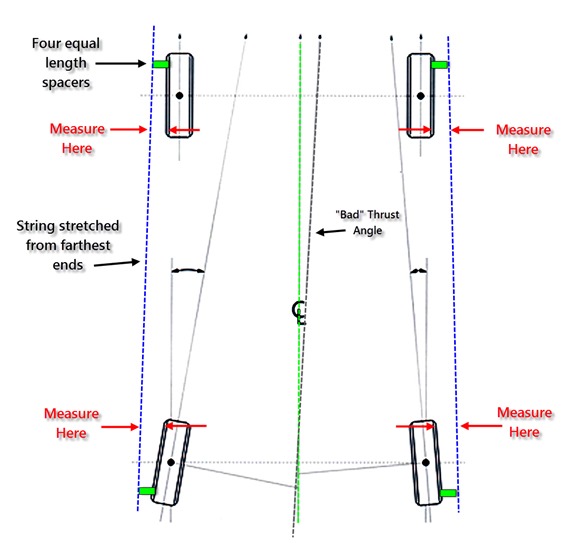

Carl's stretches his strings from the back edge of the rear wheel to the forward edge of the front. He spaces the string off the face of the wheels using equal length stand offs. He then works until the faces of the wheels are evenly spaced from side to side. Importantly he measures toe using a completely different tool.

The diagram below shows his technique set up on a vehicle with a misaligned left rear wheel resulting in a improper thrust angle. Measuring at the distance from the strings to the wheels as shown exposes this misalignment and the thrust angle variation.

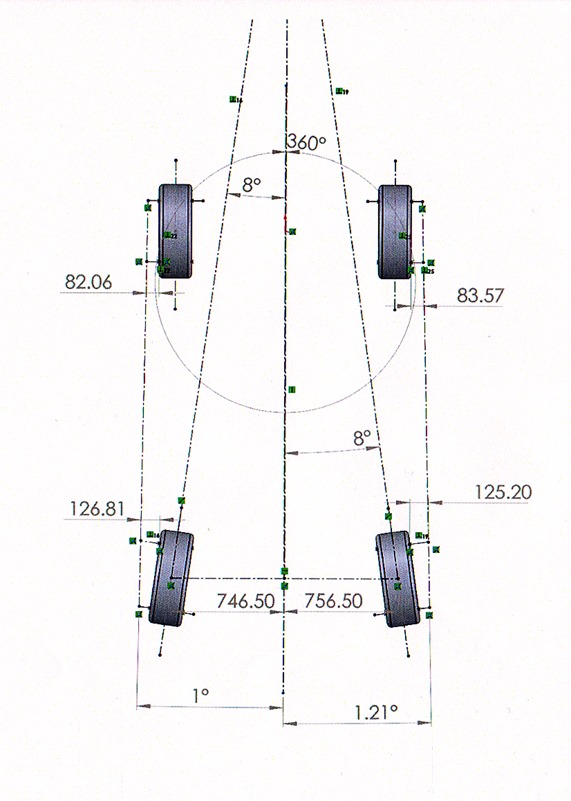

In an effort to better understand how his technique works I had PICo’s Chief Engineer Dan Oss put together a 3D model of the Lotus Exige suspension to play around with. The real genius is that the only condition that exists where the measurements from the strings are equally spaced (side to side) is when the thrust angle is "0". The first image below shows the misaligned condition.

The next image shows the aligned condition.

This third diagram shows that offsetting the rear wheels 5mm (a not unlikely condition because of manufacturing tolerances) does not adversely affect the precision inherent in this method.

Finally an animated series of images from the Solidworks model showing the relationships between the individual wheels as the system moves from aligned to misaligned… and back.

Thanks for the great explanation. It took me a long time to figure out how to get the rear toe even. In 87 i had a new 911 that i took to a dealer for alignment . Driving it home it was so far off it was dog tracking . I never could find a shop that would take the time to do it right.Most of the time when you hear string alignment they are using it to square the car. That works only if you can accurately measure off the center-line of the car. On a race car they make a jig to mount bars on the F&R. Its almost impossible to get the exact center-line on a street car. The best way to get accurate toe and thrust angle is. 1. measure total toe with a mechanical toe bar off the rims not the tires. 2. then use my string method to get an even thrust angle. This method it accurate to .005.. Carl

ReplyDeleteCarl... How nice you found this blog posting. I'm working on a "summary" posting that includes data from a Hunter alignment machine that agrees nicely with the results achieved using your system. Thank you for freely sharing your knowledge and experience with those of us learning how to do these sorts of things.

ReplyDelete